The Arctic Surface Foundation© is a foundation system intended for small to moderate sized buildings , modules, or equipment skids in remote arctic locations where seasonal and long-term ground movements are possible, and other measures to obtain and maintain a serviceable foundation system are less economical or practical. The system may be placed directly upon arctic tundra, when gravel is not available, with only minor leveling of tussocks under each bearing pad.

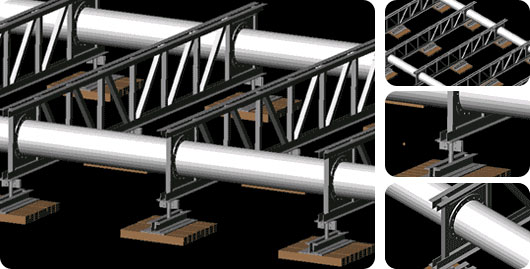

The system is an integration of:

- Steel trusses spanning one direction (normally the short plan dimension

- Large diameter torque tubes in the opposing direction, to resist the effects of differential ground settlement/heaving on warping the supporting top bearing-plane of the foundation

- Foundation bearing pads with a means of load adjustment of the individual pads

- Provision for attachment of various floor or superstructure types

The uniqueness of the system lies in the use of large diameter torque tubes to resist potential warping deformations in the plane of the top of the foundation, which may not be adequately addressed by other rectilinear framing concepts. Other “space frame” types of systems often provide less out-of-plane stiffness than the building they support, so that the building itself is providing more resistance to foundation distortions than the foundation is. Over time, these distortions to the building and its finishes, doors, and windows can become damaging and/or require costly maintenance.

Note that no surface-bearing foundation on unimproved tundra or permafrost is maintenance free, as some non-uniform thawing and settling is to be expected over time. Periodic monitoring and adjustment of the bearing pads of the Arctic Surface Foundation© is apt to be required, and the foundation system is detailed to make the adjustments as easy as possible over the long term. The Arctic Surface Foundation© does not rely on large leveling/jacking screws that are subject to corrosion over time. With the Arctic Surface Foundation© , provision for adjustment of the individual bearing pads is made by a friction clamp and jacking arrangement using light-weight portable jacking equipment, which may be required periodically. This alleviates potential difficulties overcoming the effects of corrosion when jacking adjustments must be performed by means of large screws, and the friction clamp approach simplifies utilization of the weight of the footing pads to resist net-uplift. Footing pads may be designed from pressure-treated timber, or precast concrete. Rigid insulation may be added to the bottom of the pads to further reduce heat transfer, and when timber footing pads are used, to elevate the treated timber to further retard decay due to wet conditions.

Wood nailers are normally bolted to the top surface of the steel trusses, to receive a variety of timber framing materials. The system is particularly suited for use with insulated stress-skin panels (ISSP), but can accommodate virtually any framing system. Floor and superstructure designs using non-combustible material are also compatible with the Arctic Surface Foundation©.

The foundation system is designed case-by-case for project-specific building and ground conditions. It can be designed to accommodate a variety of contingency conditions, involving various patterns of loss of ground support, or of localized ground heaving. Varying levels of system performance can be achieved, as limited by the constraints of project economics. These contingency conditions arising from non-uniform bearing support will ordinarily govern the design, and as a result, the Arctic Surface Foundation© system has a robust capacity for building code specified loadings.

For a project-specific application for the Arctic Surface Foundation©, click here to contact Mark.

OWNERSHIP AND USE OF INTELLECTUAL PROPERTY

The Arctic Surface Foundation© 2003, with its integration of features and details described herein is an innovative foundation design concept, and as such, is the intellectual property of Mark D. Anderson, consulting engineer. Mark D. Anderson, consulting engineer retains all common law, statutory, and other reserved rights, including the copyright and the patent rights thereto.